Meridian™ Key Features

Meridian™ API 6D valves are developed in partnership with customers and manufacturers incorporating ongoing feedback. A vast amount of industry experience and technical expertise has resulted in distinguishing features that offer our customers superior products with several advantages. In addition to meeting or exceeding the specifications offered by top-tier manufacturers,

- Meridian™ valves come with an industry leading 4 year warranty period

- Certification process has been completed to offer our customers valves that can be used in SIL applications

- A focused effort has gone into developing high resolution drawings with complete valve details

- Meridian™ chooses to use high-phosphorus EN to elicit performance in even more corrosive applications than standard ENP

- All API 6D ball valves are subject to a strict testing sequence involving high pressure hydrostatic seat test followed promptly by a low pressure pneumatic seat test to ensure performance in dynamic pressure conditions

- Our innovative CHECKPOINT® process for monitoring critical control point data during manufacturing allows a very high level of quality and manufacturing control.

Warranty

Meridian™ provides an industry leading warranty of 48 months from date of shipment or 24 months from the date of start-up (whichever is sooner) for all Meridian™ brand API 6D check valves, trunnion ball valves, and floating ball valves.

SIL

Meridian™ 3 piece forged trunnion ball valves and 2 piece cast floating ball valves are SIL rated. Certification available upon request.

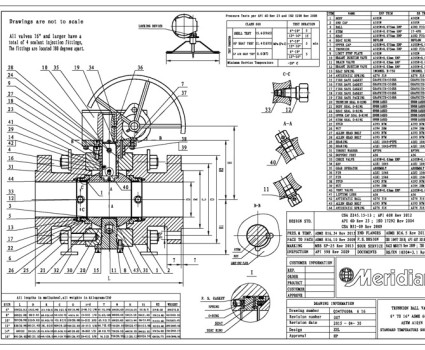

Meridian™ Drawings

Countless hours have been invested in reviewing and developing accurate drawings for all Meridian™ API 6D valves. For each individual valve offered, all details are consolidated in the drawing including:

- Complete pressure test data including type of test, media, pressures and durations

- Detailed material breakdown for every component in the valve with full descriptions and specifications for metallurgy

- Alternative trim options including ENP or stainless steel with exact metallurgy for all components

- All applicable specifications for design, testing, marking and documentation

- Complete labeling of all components of the valve easily viewed in high-resolution

- Title block with drawing description including size(s), pressure class and intended service

- Envelope dimensional data in both imperial and metric.

ENP or Stainless Steel Trim

High Phosphorus 3 mil ENP Trim Upgrade

Meridian™ has improved the standard ball valve trim in our Floating and Trunnion Ball Valves by upgrading the normal Electroless Nickel-Phosphorus plating to a 3 mil High phosphorus EN Plating. The phosphorus content exceeds 10%.

Meridian’s ENP vs. Standard ENP

Meridian’s 3 mil High phosphorus versus the standard ENP provided by other manufacturers:

- High phosphorus EN plating is less porous which increases corrosion protection and provides enhanced wear resistance.

- High phosphorus EN plating has the highest deposit passivity rating meaning that it is less reactive with the process fluids. This is known as corrosion resistance. This allows high phosphorus platings to be used in pH conditions as low as 4. Standard ENP should only be used for pH above 5. This difference is very important in the energy industry where process conditions are often acidic.

- The corrosion performance of EN plating is proportional to the deposit thickness. Meridian’s 3 mil plating thickness is an excellent barrier protecting the substrate material (commonly A105N or A350 LF2). A thinner 1 mil ENP should be limited to valves in sweet service and a relatively neutral pH process.

Meridian’s ENP vs. Full 316 SS

Meridian’s 3 mil High phosphorus EN Plating versus a full 316 Stainless Steel trim:

- Meridian’s high phosphorus EN plating has a Vickers hardness of 480 – 500, 316 stainless steel is very soft and has no stated ASTM hardness level. This extreme hardness helps an EN plated ball resist scratches that quickly damage the seat material and compromise the valve seal.

- EN plating is allowed by NACE MR-0175 / ISO 15156 and is suitable for higher temperatures than 316 Stainless Steel. 316 Stainless Steel is limited to a maximum of 140°F (60°C) due to dangerous interactions with chlorides above these temperatures.

- Electroless Nickel plating leaves a surface coating of approximately 90% pure nickel. Nickel is a noble metal that provides the corrosion resistant performance required in difficult services. 316 Stainless Steel also relies on nickel for corrosion resistance but is limited to 10 – 14% nickel by weight.

Low Pressure Air Testing

Typical floating ball valves with jam seats seal well either under high pressure or low pressure conditions. If this valve is subject to both high and low pressure during service, its chances of premature failure are very likely. Jam seats cannot accommodate the stress of high pressure sealing and will deform permanently. Meridian™ uses a flexible lip and heel design to ensure seats flex to accommodate high pressures without deforming and can then provide bubble tight seal at low pressure as well. Meridian™ API 6D floating ball valves ALL have high pressure hydrostatic seat test and a low pressure pneumatic seat test performed. Meridian™ API 6D trunnion mounted ball valves are also all tested with high pressure hydrostatic and low pressure pneumatic seat tests.

CHECKPOINT®

For API 6D product, our internal manufacturing and process quality system leverages “critical control point” data to provide a high level of quality and manufacturing control. Key components of the CHECKPOINT® process include:

- A database that links CHECKPOINT® manufacturing plant input to a specific valve serial number.

- Visual review and/or inspection and sign-off at each stage in the process.

- Checklist / traveler for each valve / component in production that tracks its progress from raw material to finished product.

- Ability to monitor CHECKPOINT® data remotely.