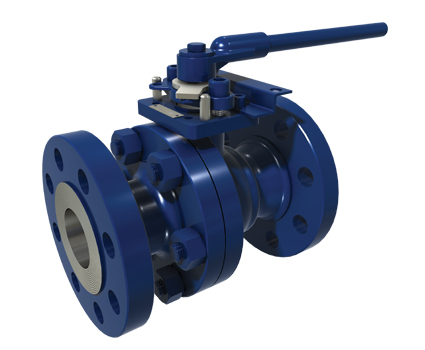

Meridian™ Bolted Two Piece Floating Ball Valve

Design Standards

- 2 piece bolted body design for ease of field service and maintenance

- Cast steel 150, 300 & 600

- Forged steel 600, 900 & 1500

- Fire safe design

- Standard valves meet NACE

- Extreme low torque for actuation savings

- ISO 5211 mounting flanges

- High life cycle

- Independent dual body seals

- Locking device to API 608

- All o-rings are AED (anti-explosive decompression) design

- Gear operators and lifting lugs on 6” bore and larger

- Standard document package BS/EN 10204-3.1

- Low emission capable due to O-ring design

- Exceeds ASME B16.34 minimum wall thickness

- All MeridianTM 3 piece forged trunnion ball valves and 2 piece cast floating ball valves are certified for use in Safety Integrity Level (SIL 3) applications.

Stem Design Features

- Blowout proof stem

- Double antistatic stem

- Adjustable packing

- Triple independent low emission stem seals ensure stem seal integrity

- 2-bolt gland flange

Seat Design Features

- Unique wide flexible seat rings

- Absolute seal in low and high pressure

- RPTFE (15-20% carbon fibre) in 150 & 300 ASME; Devlon V in 600-1500 ASME

- Self-relieving seats for automatic internal cavity relief

Optional Features

- Body may be coated for corrosion protection

Doc(s)

Floating Ball Valve SpecsMeridian API 6D Floating Ball CatalogueFloating Ball Valve IOMMeridian™ Bolted Two Piece Floating Ball Valve Doc(s)

TrimPressure TemperatureAPI 6D Quality WarrantyReference Standards

Design Standard:

- API 608

- API 6D

- CSA Z245.15

- CSA B51-09

- ISO 17292

Face to Face:

- ASME B16.10

Flange:

- ASME B16.5

Marking:

- MSS SP-25

Inspection:

- API 598

Pressure & Temp.:

- ASME B16.34

Quality:

- MSS SP-55

Fire Safe Design:

- ISO 10497, API 607

Sour:

- NACE MR 0175

- ISO 15156-2009

Pressure Testing:

- API 6D and low pressure air seat test

Safety Integrity Level:

- SIL 3